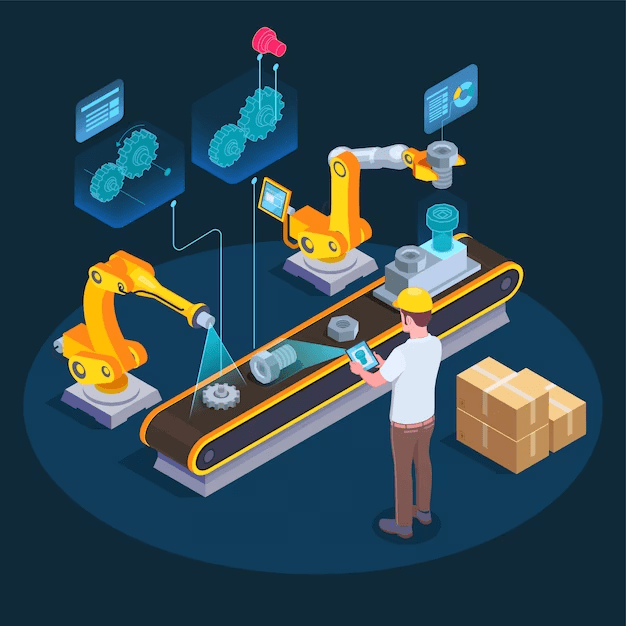

In the dynamic landscape of manufacturing, a transformative wave is sweeping through the industry, propelled by the advent of generative AI platforms. These platforms are not just technological innovations; they are catalyzing forces reshaping how manufacturers approach design, production, and efficiency. This article explores the profound impact of generative AI platforms on manufacturing, delving into their key features, operational benefits, and the promising future they bring to the forefront.

Generative AI Platforms: A Revolution in Manufacturing

Generative AI platforms designed specifically for manufacturing herald a departure from traditional systems. Where conventional manufacturing relies on predefined processes, generative AI platforms introduce adaptability and intelligence into the manufacturing ecosystem. This shift towards a more dynamic and intelligent approach holds the key to unlocking unprecedented efficiencies and innovations in the manufacturing sector.

Key Features Driving Manufacturing Transformation

- Design Optimization: A standout feature of generative AI platforms for manufacturing is their prowess in optimizing product design. Through the analysis of extensive datasets and consideration of diverse parameters, these platforms generate design alternatives that meet specific criteria. This not only fosters more efficient and resource-effective designs but also serves as a catalyst for innovation in product design.

- Process Innovation: Manufacturing processes are inherently complex, involving numerous variables. Generative AI platforms excel in analyzing these intricacies. By utilizing historical data, real-time feedback, and production parameters, these platforms propose innovative process optimizations. This not only enhances operational efficiency but also contributes to waste reduction and improved production quality.

- Supply Chain Optimization: An efficient supply chain is the backbone of manufacturing success. Generative AI platforms analyze supply chain data to predict demand patterns, recommend optimal inventory levels, and identify potential disruptions. This proactive approach minimizes delays, reduces costs, and ensures a more responsive and efficient supply chain.

- Quality Assurance through Proactive Analysis: Quality control is paramount in manufacturing, and generative AI platforms contribute to a proactive quality assurance system. By analyzing data from production processes and quality control measures, these platforms identify patterns and anomalies, minimizing defects and elevating overall product quality.

- Resource Utilization for Sustainability: As sustainability becomes a focal point, generative AI platforms play a crucial role in resource optimization. Analyzing data related to machinery usage, energy consumption, and labor patterns, these platforms recommend strategies for resource optimization. This not only reduces environmental impact but also aligns manufacturing processes with sustainable practices.

Impact on Manufacturing Operations: Realizing Operational Excellence

The integration of generative AI platforms into manufacturing operations unlocks numerous operational benefits:

- Heightened Operational Efficiency: Automation of design optimization, process innovation, and supply chain management reduces manual effort, allowing manufacturing teams to focus on strategic tasks.

- Innovative Product Design: Generative AI platforms foster innovation by generating design alternatives that may not be immediately apparent through traditional methods. This results in groundbreaking product designs that meet or exceed customer expectations.

- Responsive Supply Chain: Proactive supply chain optimization ensures materials are available when needed, minimizing lead times and preventing delays. This results in a more responsive and efficient manufacturing process.

- Proactive Quality Control: The ability to proactively identify and address quality issues during production leads to higher overall product quality. This not only reduces defects but also enhances customer satisfaction and brand reputation.

- Resource Efficiency and Cost Savings: Resource utilization optimization leads to cost savings, as manufacturing processes become more streamlined, energy-efficient, and sustainable. This contributes to the overall financial health of the manufacturing operation.

Navigating Implementation Challenges

While the benefits are evident, successful implementation of generative AI platforms for manufacturing requires addressing challenges such as data security, technology integration, and employee upskilling. Manufacturers must navigate these challenges to fully capitalize on the potential of these platforms.

Looking Ahead: The Future of Generative AI in Manufacturing

As technology continues to advance, the future of generative AI platforms in manufacturing holds immense promise. The integration with emerging technologies such as the Internet of Things (IoT) and augmented reality is expected to further enhance their capabilities, providing manufacturers with comprehensive solutions to increasingly complex challenges.

In conclusion, the adoption of generative AI platforms for manufacturing marks a pivotal moment for the industry. By harnessing the power of generative AI, manufacturers can drive innovation, optimize processes, and maintain a competitive edge. These platforms represent the forefront of technological evolution, reshaping the future of manufacturing in profound and unprecedented ways.